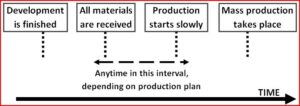

Pre-Production Inspections(PPI) allows you to stay well ahead of issues before they become production or quality nightmares.

Conducting a Pre-Production Inspection before you begin actual mass production, is crucial. Whether at the factory or your vendor’s office, our inspection team will ensure all your requirements are understood and being met before production beginning.

It focus on kinds of material to be used, process to be followed in the proceedings of production, inspection of material prior to production, checking of factory facilities & machinery, and measuring & testing equipment , so as to decrease the quality risks. Also clients may request to inspect prototype, or the making of the first few production samples, or the process of mass production as well.

Benefits of Pre-Production Inspection

Cost Savings: Detecting and addressing issues before mass production begins can save manufacturers significant costs associated with rework, scrap, and delays.

Improved Product Quality: PPI ensures that only high-quality materials and components are used, leading to better final products and higher customer satisfaction.

Enhanced Efficiency: By verifying production readiness, PPI helps streamline the manufacturing process, reducing downtime and improving overall efficiency.

Stronger Supplier Relationships: Regular PPI encourages suppliers to maintain high standards, fostering stronger and more reliable partnerships.