Pre-Shipment Inspection (PSI) is a quality control process conducted before goods are shipped to the buyer. It ensures that the products meet the agreed-upon specifications, standards, and regulatory requirements before they leave the supplier’s location.

Key Objectives of Pre-Shipment Inspection:

- Quality Verification – Checks for defects, functionality, and compliance with buyer’s requirements.

- Quantity Confirmation – Ensures the correct number of items are packed and ready for shipment.

- Compliance Check – Verifies adherence to safety, industry, or international standards (e.g., ISO, CE, ASTM).

- Packaging & Labeling Inspection – Confirms proper packaging to prevent damage and correct labeling (barcodes, shipping marks, etc.).

- Preventing Disputes – Reduces the risk of rejected shipments, returns, or chargeback.

Pre-shipment Inspection(PSI) usually happens when 100% of the products are produced and above 80% of each item are packed. Through a statistical method set by inspection industrial standard, eagle eyes inspector will sample products to verify goods overall quality, covering quantity, workmanship(AQL), specification, labeling, package, function checking and safety testing, carton drop test etc. This ensures that your product is consistent and compliant with the targeted country, industry, specified requirements and that no critical major or unacceptable defects appears.

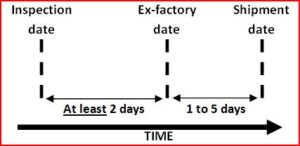

It is strongly suggested pre-shipment inspection should happen at least 2 days before ex-factory date, so clients have time to review the report and the issues found during the inspection can be remedied by factory before shipment.

Common Inspection Methods:

– AQL Sampling (Acceptable Quality Level) – Random checks based on statistical sampling (e.g., MIL-STD-105E, ANSI/ASQ Z1.4).

– 100% Inspection – Every single unit is checked (used for high-value or critical items).

– Functional Testing – Ensures products work as intended.

– Visual Inspection – Checks for physical defects, color, size, etc.

Industries That Commonly Use PSI:

– Consumer goods (electronics, toys, apparel)

– Industrial & automotive parts

– Food & pharmaceuticals

– Construction materials

Benefits of Pre-Shipment Inspection:

– Reduces defects & returns

– Ensures compliance with buyer/country regulations

– Avoids costly delays & customs issues

– Builds trust between buyer & supplier