The key inspection processes for electrical sockets

Critical Inspection Processes for Electrical Sockets

Documentation Verification

Check compliance certificates (e.g., UL, CE, TUV, RoHS)

Review product specifications against purchase order requirements

Confirm packaging/labeling accuracy (voltage/current ratings, warnings)

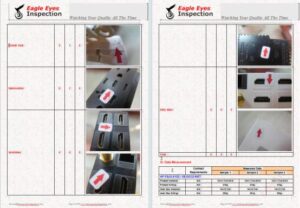

Visual Inspection

Housing integrity: No cracks, deformations, or sharp edges

Contact slots: Proper shape/size (e.g., NEMA 5-15, BS 1363, etc.)

Color consistency and surface finish quality

Correct branding/marking permanence

Dimensional & Mechanical Checks

Verify plug slot spacing with go/no-go gauge

Test grounding pin alignment (if applicable)

Confirm mounting hole positions and screw compatibility

Check shutter mechanism operation (safety sockets)

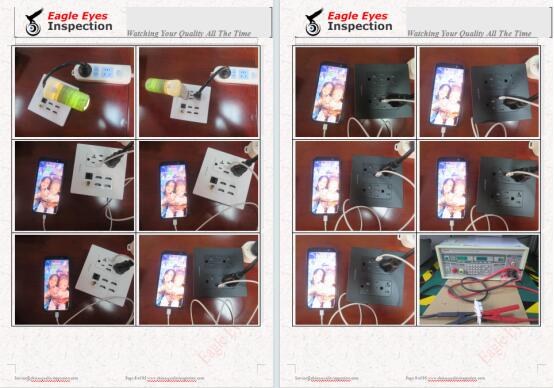

Electrical Safety Testing

Insulation resistance test (≥5MΩ at 500V DC)

Dielectric strength test (e.g., 2000V AC for 1 minute)

Continuity verification of live/neutral/ground paths

Polarity check for wiring terminals

Functional Testing

Insertion/extraction force test (using certified plug testers)

Contact grip strength measurement

Switch operation (for switched outlets)

Tamper resistance verification (if applicable)

Material & Durability

Flame retardancy check (UL94 V-0 or equivalent)

Terminal screw torque retention test

Impact resistance assessment (IK rating where required)

Packaging Audit

Shock/vibration protection adequacy

Moisture barrier inspection (for sea shipments)

Retail packaging completeness (manuals, accessories)