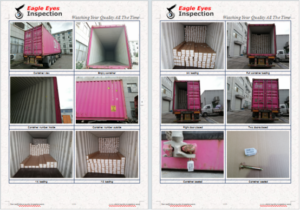

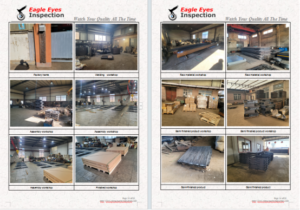

Incense Sticks AQL Inspection

PSI process for Incense Sticks; Randomly Selected Samples: AQL sampling inspection is a statistical method that randomly selects a small number of products (samples) from a batch of products for inspection to determine whether the batch of products are qualified. Product quality inspection; Product workmanship, color, specifications, function, barcode, etc will be checked based on customer’s requirements. Measured data(Product size,Outer Carton size) Special test for Incense Sticks 1 Function…