Eyewash Stations Inspection Process and Key Points

Eyewash stations are critical safety devices designed to provide immediate decontamination in case of chemical exposure to the eyes or face. Regular inspections ensure they function correctly when needed. Below is a detailed inspection process and key points to check.

1. Inspection Frequency

Weekly: Basic functionality check (mandatory per ANSI Z358.1 standard).

Monthly: More thorough inspection (including water flow and cleanliness).

Annually: Comprehensive inspection, including plumbing and compliance verification.

2. Eyewash Station Inspection Checklist

A. Accessibility & Location

Clear Access: No obstructions within a 10-second reach (about 55 ft / 16.7 m).

Proper Signage: Clearly marked with visible signage.

Well-Lit Area: Adequate lighting for emergency use.

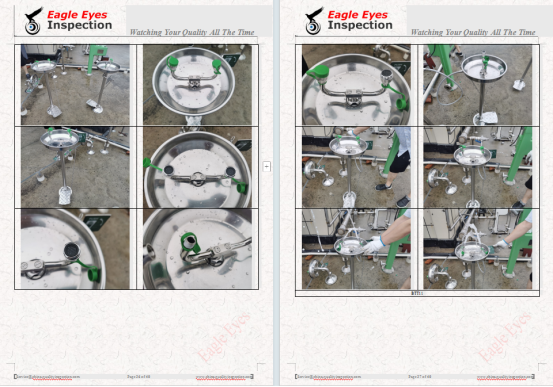

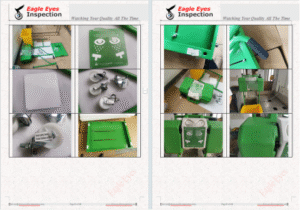

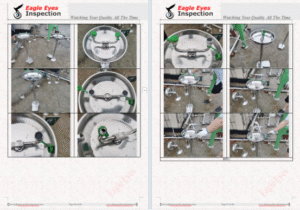

B. Physical Condition

No Leaks or Damage: Check hoses, nozzles, and valves for cracks or corrosion.

Dust Caps Intact: (If applicable) Caps should be in place to prevent contamination.

Nozzles Clean & Unclogged: Ensure no debris or mineral deposits block water flow.

C. Water Flow & Temperature

Flow Rate:

Eyewash: ≥ 0.4 GPM (1.5 L/min) for 15 minutes.

Eye/Face Wash: ≥ 3.0 GPM (11.4 L/min) for 15 minutes.

Water Temperature: Tepid (60°F–100°F / 16°C–38°C) to prevent thermal shock.

Steady Stream: Water should flow smoothly without splashing excessively.

D. Activation & Operation

Quick Activation: Should turn on in 1 second or less (hands-free for plumbed units).

Continuous Flow: Must run without needing manual hold (ANSI requirement).

Self-Draining: No standing water that could breed bacteria (for plumbed units).

E. Compliance & Documentation

ANSI Z358.1 Compliance: Verify model meets latest standards (2014 or newer).

Inspection Log: Record date, inspector name, and any corrective actions.