Key Inspection Processes for Socks (QC Checklist)

Here’s a standardized workflow for sock inspection:

1. Pre-Production Inspection (PPI)

Material Verification: Check fabric composition (e.g., cotton, polyester, spandex) against specifications.

Lab Testing: Confirm colorfastness, shrinkage, pilling resistance, and durability.

Sample Approval: Validate stitching, elasticity, and design alignment with tech packs.

2. During Production Inspection (DPI)

In-Line QC: Monitor stitching consistency, seam strength, and pattern alignment.

Size/Weight Checks: Ensure uniform sizing and weight per product standards.

3. Final Random Inspection (FRI) – AQL-Based

(Follow ISO 2859-1 AQL Levels, typically 2.5 for minor defects, 1.0 for major defects)

A. Visual Inspection

Fabric Defects: No holes, stains, or uneven dyeing.

Stitching/Seams: Flatlock seams (no raw edges), reinforced heels/toes.

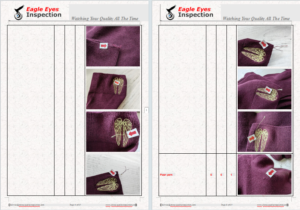

Print/Embroidery: Logo placement, color accuracy, and symmetry.

B. Functional Checks

Elasticity Test: Cuff retains stretch after repeated use.

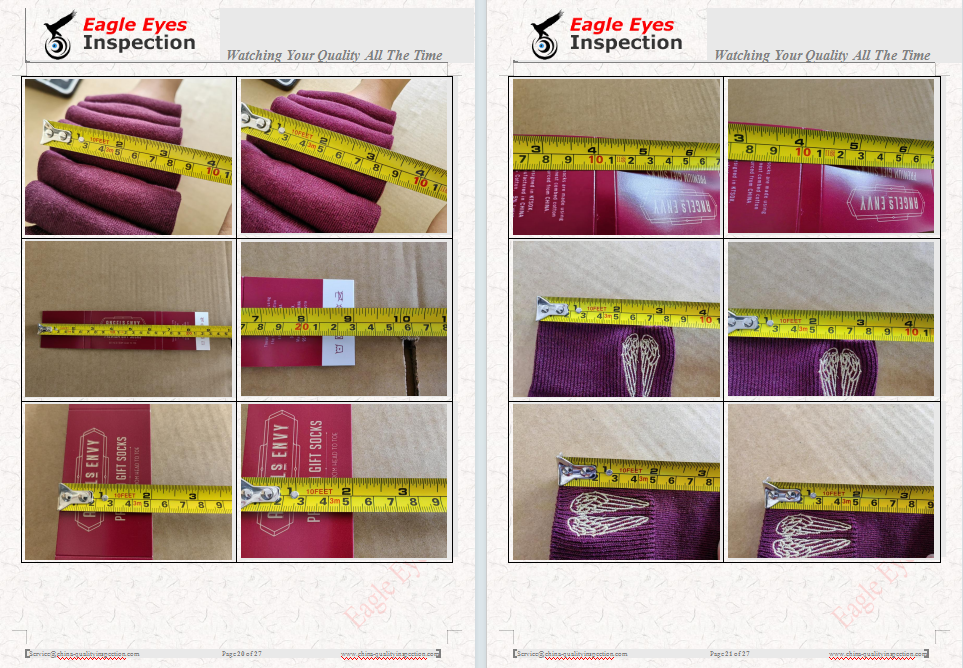

Size Measurement: Length, width match spec sheet (tolerance ±5%).

Color Consistency: No shade variation within pairs.

C. Packaging & Labeling

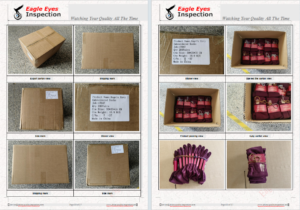

Pair Matching: Socks are correctly paired and folded.

Labels: Care instructions, size tags, barcodes comply with regulations (e.g., EU/US standards).

Polybag Safety: Breathable packaging; suffocation warnings if applicable.

4. Defect Classification

Critical: Safety issues (e.g., sharp objects).

Major: Broken stitches, incorrect sizing – likely to cause returns.

Minor: Minor thread pulls – may not affect usability.

5. Documentation

Inspection Report: Includes defect photos, measurements, and pass/fail status.

Corrective Actions: Supplier must address failures (e.g., rework/replacement).