The key inspection processes for footballs (soccer balls) can be summarized as follows:

1. Visual Inspection

Check for any visible defects (scratches, dents, discoloration).

Verify the alignment of panels and print quality (logos, graphics).

Ensure stitching is even and free from loose threads.

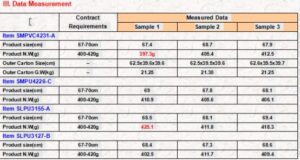

2. Dimensional & Weight Check

Measure circumference (standard: 68–70 cm for Size 5).

Verify weight (410–450 grams for FIFA-approved balls).

Check sphericity (roundness) by rolling the ball.

3. Material Quality Test

Inspect outer cover material (leather, PU, PVC) for durability.

Check bladder (latex or butyl) for air retention.

4. Stitching & Bonding Quality

Hand-stitched balls: Ensure tight and uniform stitching.

Thermally bonded balls: Check for secure panel adhesion.

5. Bounce Test

Drop the ball from 2 meters and check rebound height (should be 50–65% of drop height).

6. Air Retention Test

Inflate to recommended pressure (0.6–1.1 bar / 8.7–16 psi).

Leave for 24 hours and check pressure loss (should not exceed 20%).

7. Water Absorption Test (if applicable)

Submerge the ball in water and check weight gain (should be minimal for high-quality balls).

8. FIFA Quality Certification (if applicable)

Verify if the ball meets FIFA Quality Pro, FIFA Quality, or IMS standards.

9. Final Functional Test

Kick and pass the ball to assess flight stability and grip.