Key Inspection Process for Lead Strips

Inspecting lead strips is critical to ensure quality, safety, and compliance with industry standards (e.g., construction, radiation shielding, batteries). Below is a structured lead strip inspection process in English:

1. Pre-Inspection Preparation

Document Review

Verify purchase order, material specifications (e.g., ASTM B29 for lead purity ≥99.9%), mill test reports (MTR), and QC certificates.

Check compliance with standards (e.g., ISO 9001, RoHS for hazardous substances).

Tools & Equipment

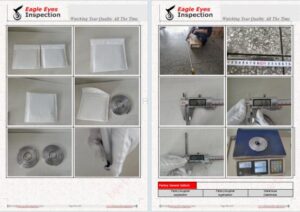

Measuring tools: Calipers (±0.01mm accuracy), micrometer, digital scale.

Testing devices: XRF analyzer (composition), hardness tester, thickness gauge (for coated strips).

2. Visual Inspection

Surface Quality

Check for smoothness, absence of cracks, pits, oxidation (white corrosion), or uneven edges.

Verify coating integrity (if applicable, e.g., PVC-coated lead strips).

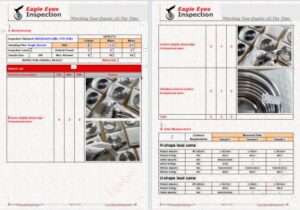

Dimensional Check

Measure width, thickness, length, and weight against specifications (tolerance typically ±2%).

3. Material & Composition Testing

Purity Analysis

Use X-ray fluorescence (XRF) to confirm lead purity (e.g., 99.9% pure lead for radiation shielding).

Test for impurities (e.g., antimony, tin, copper per ASTM standards).

Hardness Test

Shore or Brinell hardness test to ensure softness/malleability (pure lead: ~4–5 HB).

4. Functional & Performance Tests

Density Verification

Weigh and measure volume to calculate density (pure lead: ~11.34 g/cm³).

Corrosion Resistance

Salt spray test (ASTM B117) or acid exposure test for industrial applications.

Bend Test

Check ductility by bending samples (no cracking for malleable lead).

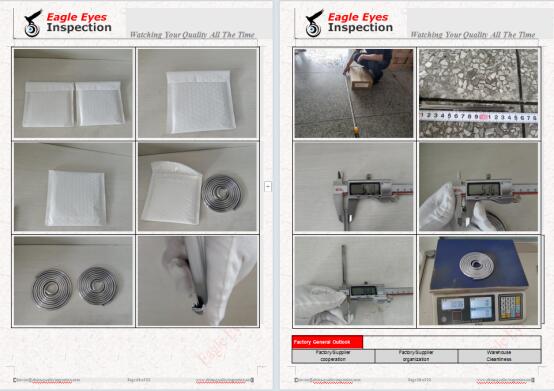

5. Packaging & Labeling

Ensure proper packaging (moisture-proof for storage).

Labels must include:

Material grade (e.g., Pb99.9), batch/lot number, dimensions, weight, and safety warnings (if toxic).

6. Final Documentation & Reporting

Issue an Inspection Report with:

Test results (pass/fail), non-conformities (e.g., surface defects), and corrective actions.

Photos of defects (if any) for supplier feedback.