Carbon Filter Inspection Process

Regular inspection of carbon filters is essential to ensure optimal performance, longevity, and safety in air/water purification systems. Below is a step-by-step inspection process:

1. Pre-Inspection Preparation

Review Manufacturer Guidelines: Check the recommended inspection frequency and procedures.

Safety Measures:

Turn off and isolate the system (for HVAC, water filters, etc.).

Wear PPE (gloves, mask, goggles) if handling spent carbon.

Tools Needed:

Flashlight

Pressure gauge (for flow systems)

Moisture meter (if applicable)

Replacement carbon (if testing efficiency)

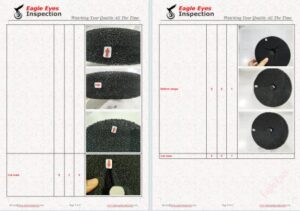

2. Visual Inspection

Exterior Condition:

Check for cracks, leaks, or corrosion in the filter housing.

Ensure seals/gaskets are intact.

Carbon Bed Inspection:

Open the filter housing (if accessible).

Look for channeling (uneven carbon distribution).

Check for excessive dust or fines (indicates breakdown).

Inspect for moisture/mold (if used in humid environments).

3. Performance Testing

For Air Filters:

Odor Detection: If the filter no longer removes odors effectively, it may be saturated.

Airflow Measurement: Use a manometer to check pressure drop (high indicates clogging).

For Water Filters:

Flow Rate Check: Reduced flow may mean clogging.

Taste/Odor Test: If contaminants are detectable, replacement may be needed.

Chlorine Test (for activated carbon): Use a chlorine test kit to verify removal efficiency.

4. Carbon Quality Assessment

Activation Check:

If possible, send a sample for lab testing (iodine number, molasses efficiency).

Alternatively, use an adsorption test (e.g., dropping a small amount of dye to see if it’s absorbed).

Lifespan Estimation:

Compare usage duration vs. manufacturer’s recommended replacement interval.