Introduction to Pre-Shipment Inspection

Imagine waiting months for a shipment, only to discover that the goods you receive are defective or don’t meet your requirements. Sounds complex? This is where pre shipment inspection—often called pre-shipment inspection or PSI—steps in as a crucial quality assurance and risk-mitigation tool for today’s global supply chains.

At its core, a pre-shipment inspection is a systematic quality control process performed by independent inspection agencies. It involves thoroughly checking products before they leave the manufacturer’s premises. The goal? To ensure goods meet buyer specifications, industry standards, and regulatory requirements—before they’re loaded for shipment. For importers, sourcing managers, and business owners, PSI is more than just a box to tick; it’s a proactive strategy to minimize costly surprises, avoid shipment delays, and protect brand reputation.

- Risk Reduction: By catching defects early, PSI helps both buyers and sellers avoid disputes and financial losses.

- Quality Assurance: Importers gain confidence that products match agreed-upon specs and standards.

- Regulatory Compliance: Many countries require PSI certificates for customs clearance, making inspections essential for smooth import processes.

In this guide, you’ll discover:

- The true meaning and objectives of pre-shipment inspection

- How PSI shapes international trade and protects your interests

- Step-by-step breakdowns of the inspection process

- Tips for preparing, choosing the right partner, and interpreting inspection results

Whether you’re a seasoned importer or new to global sourcing, understanding pre-shipment inspection is your first step toward building a resilient, transparent, and reliable supply chain. Let’s dive deeper into what makes PSI a cornerstone of successful international trade.

What Is Pre-Shipment Inspection Really About

When you hear the term pre shipment inspection, what comes to mind? Is it just a quick check before products leave the factory, or something more comprehensive? If you’re new to global sourcing—or even if you’ve managed imports for years—you’ll notice that the pre shipment inspection meaning goes far beyond a cursory glance at finished goods.

Defining Pre-Shipment Inspection (PSI)

At its core, a pre-shipment inspection (PSI) is a systematic quality control process that takes place after production is complete but before goods are shipped from the supplier to the buyer. You might see it called “final inspection” or simply “PSI” in industry circles—the terms pre shipment inspection and pre-shipment inspection are used interchangeably, but they all point to the same critical checkpoint in the supply chain. The primary goal? To ensure products match the buyer’s expectations, contractual terms, and regulatory requirements before leaving the manufacturer’s premises (Tetra Inspection).

Unlike routine in-process checks, PSI is typically conducted by independent third-party agencies, government authorities, or sometimes in-house quality teams. This impartial approach helps build trust, minimize disputes, and protect both buyers and sellers from costly surprises.

Industry Terminology and the Role of PSI

So, what does a PSI actually involve? Imagine you’re importing electronics, garments, or industrial components. Without direct oversight, how can you be sure the shipment meets your standards? That’s where PSI steps in as a safeguard. The process is structured, thorough, and tailored to each order’s unique requirements. It’s not just about finding problems—it’s about confirming everything is right before the goods are loaded for export (Pro QC).

Core Objectives of Pre-Shipment Inspection

What are the main goals of a pre shipment inspection? Here’s a clear breakdown:

- Verifying Quantity: Ensuring the number of goods matches the purchase order—no shortages or overages.

- Assessing Quality: Checking for defects, confirming materials and workmanship meet specified standards, and performing functional or safety tests.

- Packaging Review: Examining packaging for durability, suitability, and compliance with shipping and regulatory requirements.

- Marking and Labeling: Verifying that product and carton labels are correct, legible, and compliant with destination market rules.

- Compliance with Buyer Requirements: Ensuring the shipment aligns with all contractual terms, technical specs, and relevant regulations—whether that’s CE marking for Europe, FDA for the US, or other standards.

In practice, a PSI might involve visual inspections, measurements, random sampling (often using international standards like ISO 2859 or ANSI/ASQ Z1.4), and detailed documentation review. Functional tests are also common—think powering up electronics or stress-testing mechanical parts.

By systematically addressing these objectives, a PSI not only helps prevent shipment delays and costly returns but also builds confidence between trading partners. It’s a proactive step that empowers importers and exporters alike to move forward with peace of mind.

Next, let’s explore why countries and global markets rely so heavily on PSI—and how it shapes the landscape of international trade.

Why Pre-Shipment Inspections Are Crucial for Global Trade

When you’re sourcing products internationally, have you ever wondered why some shipments glide through customs while others face costly delays or even rejection? The answer often comes down to one critical step: pre shipment inspection. But what makes this process so vital for global trade—and why do so many countries and industries rely on it?

Protecting Buyers and Enhancing Trust

Imagine you’re an importer receiving goods from halfway around the world. Without direct oversight, how can you ensure those goods match your order—both in quality and quantity? That’s where pre-shipment inspection steps in as your first line of defense. By verifying products before they leave the supplier, PSI helps importers avoid receiving substandard or non-compliant goods, minimizing disputes and financial loss.

- Reduces risk: Detects defects or discrepancies before shipment, saving time and money.

- Builds trust: Provides objective third-party reports, fostering transparency between buyers and suppliers.

- Prevents disputes: Offers clear documentation to resolve disagreements quickly.

Meeting Regulatory Requirements: Why Countries May Require PSI

Countries may require pre shipment inspections because they want to:

- Protect consumers and public safety: Ensuring imported goods meet national safety standards, labeling rules, and technical regulations.

- Prevent fraud and under-invoicing: Verifying declared values and classifications to ensure accurate customs duties and taxes are paid.

- Safeguard foreign exchange reserves: Historically, some developing nations used PSI to control capital outflows and manage trade balances.

- Streamline customs clearance: A valid PSI certificate can speed up import processes and reduce bottlenecks at the border.

Not every country mandates PSI for all imports, but for certain product categories or high-value shipments, it’s often a legal requirement. For example, countries like Kenya, Nigeria, and Saudi Arabia have specific programs or regulations that make PSI mandatory for regulated goods.

Highlight: The WTO Agreement on Pre-Shipment Inspection

WTO Agreement on Pre-Shipment Inspection:

The World Trade Organization (WTO) established an agreement to ensure that PSI activities do not create unnecessary barriers to trade. The agreement outlines principles such as non-discrimination, transparency, confidentiality, avoidance of conflicts of interest, and timely dispute resolution. It also mandates that PSI procedures be fair, objective, and not cause undue delays for exporters or importers. For more, see the official WTO agreement.

Influencing Market Dynamics and Trends

The pre shipment inspection market has evolved alongside global trade. As e-commerce and cross-border sourcing have grown, so too has the demand for reliable inspection services. Today, PSI is not just about compliance—it’s a strategic tool for managing risk, enhancing brand reputation, and ensuring customer satisfaction in an increasingly competitive landscape.

- Growth in third-party inspections: More companies are turning to independent agencies for unbiased verification.

- Technology integration: Digital reporting, real-time updates, and remote inspections are making PSI faster and more transparent.

- Shift in regulatory focus: Some countries have reduced mandatory PSI requirements to streamline trade, but voluntary inspections remain popular for quality assurance.

As global supply chains become more complex, the value of PSI continues to rise—not just as a regulatory hurdle, but as a proactive investment in supply chain resilience. Next, we’ll break down exactly how a typical pre-shipment inspection unfolds, step by step, so you know what to expect.

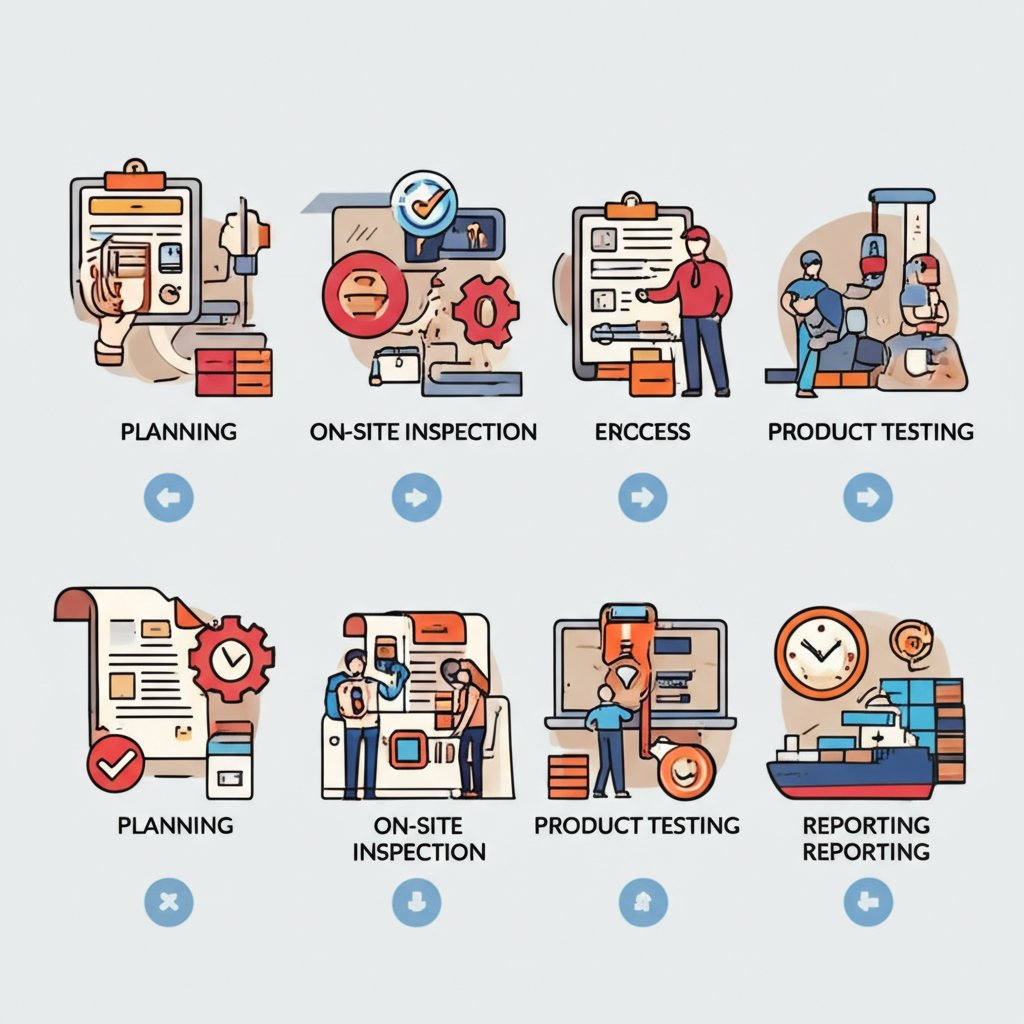

Breaking Down the Pre-Shipment Inspection Process Step by Step

Ever wondered what really happens during a pre shipment inspection procedure? If you picture a quick glance over a few boxes, think again. The pre shipment inspection process is a structured, multi-phase approach designed to catch problems before your goods ever leave the factory floor. Let’s walk through each stage so you know exactly what to expect—and how each step protects your business.

1. Pre-Inspection Preparation: Laying the Groundwork

Before anyone sets foot in the warehouse, careful planning is essential. Imagine you’re about to inspect a shipment of electronics. You wouldn’t want surprises or missed details, right? This phase ensures everyone is clear on what needs to be checked and why.

- Review Purchase Order & Specifications: Inspectors study the purchase order, technical specs, and any regulatory requirements. This guarantees a shared understanding of the inspection criteria and the buyer’s expectations.

- Develop an Inspection Plan: The plan outlines the scope, objectives, sampling method (often ANSI/ASQ Z1.4), and timeline. This structure keeps the process focused and efficient.

2. On-Site Inspection: Where the Action Happens

This is the heart of the pre shipment inspection process. It’s not just about counting boxes—inspectors look at everything from quantity to compliance, using both visual checks and hands-on testing.

- Initial Visual Inspection:

- Inspectors scan for obvious defects and check if products match the specs.

- Quickly identifies any glaring issues before deeper checks begin.

- Quantity Verification:

- Every unit and shipping carton is counted to ensure the order matches the purchase agreement.

- Reduces the risk of shortages, overages, or unapproved substitutions.

- Sampling:

- Random samples are selected using statistical methods like the Acceptance Quality Limit (AQL).

- This ensures the inspection reflects the overall batch quality, not just a few handpicked items.

- Detailed Product Inspection:

- Visual Check: Products are examined for cosmetic defects—think scratches, dents, color mismatches, or missing parts.

- Workmanship Assessment: Inspectors evaluate assembly quality, such as welding, gluing, or stitching, against approved samples.

- Dimensional Verification: Measurements are taken to confirm product size, construction, and tolerances.

- Compliance Verification: Labels, markings, and materials are checked to ensure they meet destination market regulations and buyer requirements.

- Functional and Safety Testing:

- Products are tested to ensure they work as intended and meet performance standards.

- Safety tests are conducted to identify hazards or non-compliance with safety standards.

- Packaging Review:

- Packaging is checked for durability, correct labeling, and suitability for transport.

- Ensures goods arrive intact and are compliant with shipping and regulatory requirements.

3. Post-Inspection: Reporting and Decision-Making

Once the on-site checks are done, the focus shifts to documentation and next steps. This phase ensures transparency and supports informed decisions.

- Compile Inspection Findings: Inspectors document every observation, defect, and compliance issue. Photos and measurements back up their findings.

- Inspection Report Creation: A detailed report summarizes results and may include recommendations for corrective action.

- Stakeholder Review: The report is shared with buyers, suppliers, and quality teams for transparent decision-making.

- Approve, Reject, or Request Rework: Based on the report, stakeholders decide whether to approve the shipment, reject it, or request corrective actions and a possible re-inspection.

4. Follow-Up and Continuous Improvement

The process doesn’t always end with a single inspection. If issues are found, corrective actions are implemented—sometimes followed by a re-inspection to ensure problems are fixed. This feedback loop helps suppliers improve and reduces future risks.

- Implement Corrective Actions: Suppliers address identified issues to prevent recurrence.

- Re-Inspection (if needed): A follow-up inspection verifies that corrective actions were effective and standards are now met.

Best Practices for a Smooth Inspection

- Define clear quality criteria and communicate them to all parties.

- Use trained, knowledgeable inspectors familiar with your product type.

- Leverage digital tools for accurate, efficient reporting.

- Maintain open communication with your suppliers to resolve issues quickly.

- Continuously review and refine your inspection process based on feedback and evolving standards.

Understanding each step of the pre shipment inspection procedure empowers you to take control of your supply chain, avoid costly surprises, and build trust with your buyers and suppliers. Next, we’ll look at how this process unfolds in China—the world’s manufacturing powerhouse—so you can navigate local challenges and make the most of your inspection investment.

Navigating Pre-Shipment Inspection Services in China

When you think of sourcing products globally, China likely comes to mind first—and for good reason. But have you ever wondered why pre shipment inspection China is such a hot topic among importers? With tens of thousands of factories and a vast range of products, China is both an opportunity and a challenge. Let’s explore what makes arranging pre shipment inspection services in China unique, and how you can confidently manage quality from afar.

Why China Is the Epicenter for Pre-Shipment Inspection

Imagine placing a large order with a manufacturer thousands of miles away. How can you be sure your goods are made to spec, properly packaged, and free from defects before they leave the port? Here’s why China stands out:

- World’s Manufacturing Hub: China produces everything from electronics to textiles, making it a critical node in global supply chains.

- Complex Supplier Network: The sheer number of factories—ranging from small workshops to massive industrial parks—means product quality can vary widely.

- Distance and Language Barriers: Most importers are far from their suppliers, and communication gaps can lead to misunderstandings or missed requirements.

- Regulatory Requirements: China’s export rules and international standards add another layer of complexity, making reliable inspection essential.

Common Challenges When Arranging PSI in China

It’s easy to assume that booking a pre-shipment inspection is straightforward, but in reality, you’ll notice some unique hurdles:

- Varying Inspection Standards: Not all agencies follow the same protocols or sampling methods, which can affect consistency.

- Quality of Inspectors: Some providers may lack experience in your product category or cut corners on thoroughness.

- Geographical Coverage: Factories in remote areas may be harder to reach, impacting inspection timing and cost.

- Transparency and Reporting: Incomplete or unclear reports can leave you guessing about the real condition of your goods.

Types of Pre-Shipment Inspection Services in China

When you explore pre shipment inspection services in China, you’ll encounter several service models designed to fit different needs:

- Third-Party Inspections: Independent agencies conduct unbiased checks based on your requirements, offering flexibility and expertise.

- Supplier Self-Inspections: Some factories offer to inspect their own goods, but this approach risks conflicts of interest and lower objectivity.

- Full vs. Sampling Inspections: Full inspections review every unit (ideal for high-value or critical goods), while sampling uses statistical methods like AQL to assess batch quality efficiently.

How to Choose a Reliable PSI Provider in China

With so many options, how do you find a reputable inspection partner? Here are practical tips to guide your search:

- Check Certifications: Look for agencies with recognized credentials (such as ISO 9001 or AQSIQ license) to ensure professionalism and compliance.

- Industry Experience: Choose providers with proven track records in your product category, whether it’s electronics, textiles, or machinery.

- Service Scope: Confirm they offer on-site inspections, detailed reporting, and coverage in your supplier’s region.

- Transparent Pricing: Ask for clear quotes that include travel and reporting fees—no hidden costs.

- Customer Reviews: Research online feedback and seek recommendations from peers in your industry.

- Effective Communication: Evaluate their responsiveness and ability to provide after-sales support or answer questions post-inspection.

- Trial Runs: Consider starting with a small batch inspection to assess quality and reliability before scaling up.

Comparing Local and International Inspection Agencies

Not sure whether to go with a local Chinese agency or an international provider? Here’s a side-by-side look to help you decide:

| Criteria | Local Agencies | International Agencies |

|---|---|---|

| Pricing | Often lower, but may have variable transparency | Generally higher, but more predictable and all-inclusive |

| Inspector Experience | Varies; may be highly specialized in local industries | Typically standardized training and procedures |

| Language & Reporting | Reports may be in Chinese or basic English | Comprehensive, professional English reporting |

| Geographical Coverage | Strong local reach, especially in remote areas | Wide coverage, but may have longer lead times for remote locations |

| Compliance & Certifications | May lack international certifications | Usually hold global accreditations (e.g., ISO, AQSIQ) |

| Customer Support | May be limited or less responsive | Dedicated support and dispute resolution |

Why Working with an Experienced Partner Matters

Arranging pre shipment inspection in China doesn’t have to be overwhelming. Experienced partners like Eagle Eyes Quality Inspection simplify the process by offering certified inspectors, transparent pricing, and clear, actionable reports. Their local expertise and international standards mean you get the best of both worlds—reliability, accountability, and peace of mind at every stage of your supply chain.

Ready to take the next step? In the following section, you’ll learn how to select the best inspection company for your unique needs and ensure your products always meet expectations.

How to Choose the Best Pre-Shipment Inspection Company for Your Needs

When you’re importing products, how do you know you’re picking the best pre shipment inspection company—one that will truly safeguard your interests? Imagine the headache of a shipment arriving with defects or compliance issues simply because your inspection partner missed the mark. Sounds risky? Choosing the right provider isn’t just a formality; it’s a decision that can make or break your supply chain success, especially in dynamic markets like China.

Key Criteria for Selecting a Reliable Inspection Partner

Before you sign on with any inspection agency, take a step back and ask: What separates the best from the rest? Here are the essential factors you’ll want to weigh:

- Accreditations & Certifications: Look for ISO 9001:2015 certification, AQSIQ licensing (for China), or other recognized quality management credentials. These signal adherence to international best practices and regulatory acceptance (ECQA).

- Industry Experience: Does the company have a proven track record with your product category—electronics, textiles, machinery, or consumer goods? Experience means they know where issues hide and how to spot them quickly.

- Comprehensive Reporting: Detailed, timely, and clear inspection reports—ideally with photos, measurements, and actionable recommendations—are crucial for making informed decisions.

- Transparent Pricing: No one likes hidden costs. The best providers offer clear, all-inclusive quotes and explain what’s covered up front.

- Reputation & Testimonials: Check for positive reviews, references, and case studies. A strong reputation reflects consistent performance and customer trust.

- Global Network & Local Expertise: Especially in China, look for agencies with both a broad network and deep local knowledge. This ensures fast response times and effective communication with factories (Kale Smart Life).

- Responsive Customer Support: Quick answers and after-sales support can be a lifesaver when issues arise or urgent questions need attention.

Quick Checklist: Are You Choosing the Best?

| Selection Criteria | Why It Matters | What to Ask |

|---|---|---|

| Certifications & Accreditations | Ensures recognized quality standards | Do you hold ISO 9001:2015 or AQSIQ? |

| Industry Experience | Reduces risk of missed defects | Have you inspected products like mine? |

| Reporting Quality | Supports clear decision-making | Can I see a sample report? |

| Pricing Transparency | Prevents budget surprises | Is your quote all-inclusive? |

| References/Testimonials | Reflects real-world reliability | Can you provide client references? |

| Coverage & Local Presence | Speeds up inspections, bridges language gaps | Do you have inspectors near my supplier? |

| Customer Support | Resolves issues quickly | How do you handle urgent requests? |

Comparing Inspection Provider Types

Still debating between a local Chinese agency and an international player? Here’s a quick side-by-side to help you decide:

| Provider Type | Strengths | Potential Drawbacks |

|---|---|---|

| Local Chinese Agencies | Lower cost, strong local connections, fast onsite response | Variable reporting quality, may lack global certifications |

| International Agencies | Standardized procedures, global accreditations, detailed English reports | Higher cost, possible slower response in remote regions |

| Specialist Third-Parties (e.g., Eagle Eyes Quality Inspection) | Certified inspectors, tailored reporting, deep China expertise, transparent pricing | May have limited scope outside China (if focused regionally) |

What Makes the Best Pre-Shipment Inspection Company in China?

The best pre shipment inspection company in China goes beyond ticking boxes. They combine rigorous standards, product-specific know-how, and a commitment to transparent communication. For example, Eagle Eyes Quality Inspection stands out by offering ISO-certified inspections, on-site experts across China, and comprehensive reports with photographic evidence. Their proactive approach helps you catch issues early, negotiate with suppliers, and avoid costly surprises—so you can ship with confidence.

Choosing wisely means your supply chain is protected, your products meet buyer expectations, and your brand reputation stays strong. Next, let’s look at how to prepare your own PSI checklist and ensure every inspection covers what matters most.

Essential Checklists for a Smooth Pre-Shipment Inspection

When you’re preparing for a pre-shipment inspection, do you ever wonder how to make sure nothing slips through the cracks? Imagine the frustration of discovering a critical defect or missing paperwork after your shipment has already left the factory. That’s why a well-structured pre shipment inspection checklist—and the right forms—are your best allies for a smooth, successful inspection process.

Why Checklists and Forms Matter in PSI

Sounds simple, but the difference between a seamless inspection and a costly oversight often comes down to preparation. A pre shipment inspection form acts as your roadmap, guiding inspectors through every essential detail and helping you document findings for future reference. Whether you’re shipping electronics, apparel, or machinery, these tools ensure that nothing is left to chance.

Core Items Every Pre-Shipment Inspection Checklist Should Cover

Not sure what to include? Here’s a practical breakdown of the most important elements you’ll want to see on any PSI checklist. Think of this as your quality assurance playbook:

| Checklist Item | Purpose | Example |

|---|---|---|

| Product Specifications | Confirms item matches purchase order in design, material, and function | Model number, dimensions, color, material grade |

| Quantity Verification | Ensures shipment matches ordered quantity | Total units, cartons, batch numbers |

| Acceptance Quality Limit (AQL) | Defines the statistical sample size and defect tolerance | ANSI/ASQ Z1.4, ISO 2859-1 standards |

| Defect Classification | Organizes defects as minor, major, or critical for clear reporting | Minor: small scratch; Major: wrong color; Critical: safety hazard |

| Visual and Workmanship Checks | Identifies cosmetic flaws and workmanship issues | Dents, misalignments, poor stitching |

| Function & Safety Testing | Confirms product operates as intended and is safe | Electrical tests, mechanical function, safety certifications |

| Packaging Review | Checks packaging durability, labeling, and compliance | Box strength, correct labels, barcodes |

| Labeling & Marking | Ensures all labels meet destination requirements | CE mark, country of origin, warning symbols |

| Compliance & Documentation | Verifies certificates, manuals, and regulatory paperwork | Test reports, user manuals, compliance declarations |

Customizing Your Checklist for Product-Specific Needs

Not every shipment is the same. For example, electronics may require extra safety testing and certification checks, while textiles might focus more on colorfastness and stitching. How do you tailor your checklist?

- Review Product Specifications: Start with the purchase order and technical drawings to identify unique requirements.

- Consult Industry Standards: Use relevant standards (like ISO, ASTM, or destination country regulations) to add specific checkpoints.

- Include Buyer-Specific Needs: If your client has unique branding, packaging, or compliance needs, add these to your checklist.

By customizing your pre shipment inspection checklist, you make sure every shipment is inspected for what matters most to your business and your customers.

Where to Find Ready-to-Use PSI Checklists and Forms

Don’t want to start from scratch? Many inspection agencies and quality management platforms offer free, downloadable checklist templates and forms. These digital tools help you:

- Document inspection results in real time

- Attach photos of defects and corrective actions

- Generate reports for quick decision-making

- Ensure all findings are securely stored and easily accessible

Websites like SafetyCulture provide sample PDFs and customizable digital checklists that you can adapt for your products and supply chain needs.

Key Takeaway

A thorough pre shipment inspection checklist is your safety net—helping you catch issues early, document every step, and confidently approve or reject shipments. The right preparation today means fewer surprises tomorrow.

Next, we’ll show you how to interpret your inspection reports and certificates, so you can make informed decisions with every shipment.

Making Sense of Your Pre-Shipment Inspection Certificate and Report

When you receive your shipment’s inspection paperwork, do you ever wonder what all those details and photos really mean? If you’ve ever stared at a pre shipment inspection report or certificate and felt unsure about what to look for, you’re not alone. Let’s break down these essential documents—so you can use them with confidence to make smart decisions and keep your supply chain on track.

What’s Inside a Pre-Shipment Inspection Report?

Imagine opening your inbox and finding a freshly delivered inspection report. What should you expect? A well-structured pre shipment inspection report does more than just list pass or fail; it provides a transparent, visual, and factual overview of your goods’ condition before they leave the factory. Here are the core sections you’ll typically find:

- Executive Summary: A top-level snapshot—did the batch pass or fail based on your criteria? This section quickly tells you if your shipment is ready to go or needs attention (QIMA).

- Key Findings: A concise list of major issues, defects, or non-conformities uncovered during the inspection. This helps you zero in on what matters most.

- Detailed Results: In-depth breakdowns of quantity checks, product specifications, workmanship, labeling, packaging, and compliance with your order requirements.

- Photographic Evidence: Clear, timestamped images of inspected products, defects, packaging, and labels. These visuals are your proof and make it easy to communicate with suppliers or internal teams.

- AQL (Acceptance Quality Limit) Results: Statistical data showing how many defects were found versus the allowed threshold, based on international standards like ANSI/ASQC Z1.4 or ISO 2859-1.

- Inspector’s Comments & Recommendations: Professional observations, suggested corrective actions, and advice on next steps—whether to accept, reject, or request rework.

You’ll notice that a good report is more than a checklist—it’s a decision-making tool. By reviewing the summary, photographic evidence, and AQL data, you can quickly assess whether your shipment meets expectations or if you need to take action before goods are dispatched.

Understanding the Pre-Shipment Inspection Certificate

Now, let’s talk about the pre shipment inspection certificate. While the report dives into detail, the certificate is a formal document confirming that your goods have been inspected and found to comply with your order and relevant standards. Here’s what you’ll typically see on a certificate:

- Certificate Number: Unique identifier for traceability.

- Inspection Date & Location: When and where the inspection took place.

- Product Description & Quantity: Details of the inspected shipment.

- Reference Standards: The methods or standards used (such as ISO 2859-1 sampling).

- Inspector’s Declaration: Statement that the goods were found to meet (or not meet) the specified requirements.

- Official Stamps & Signatures: Authentication from the accredited inspection agency (HQTS).

Think of the certificate as your shipment’s passport—sometimes required for customs clearance, especially in certain African and Asian countries, and always valuable for risk management and supplier accountability.

How to Use These Documents for Smart Decisions and Compliance

So, what should you do once you have your inspection report and certificate in hand?

- Review the Summary and Photos: Quickly spot any red flags or critical defects before approving shipment.

- Check AQL Results: Make sure defect rates are within your acceptable quality limits.

- Verify Compliance: Ensure all buyer requirements, labeling, and regulatory standards are met—avoiding costly customs delays or rejections.

- Document for Traceability: Save reports and certificates as part of your quality management records. This protects you in case of disputes or recalls.

- Communicate with Suppliers: Use findings and photos to negotiate corrective actions or improvements for future orders.

In short, your pre shipment inspection report and certificate are more than paperwork—they’re your assurance that what you ordered is what you’ll receive. By reading these documents closely and using them to guide decisions, you protect your business, satisfy regulatory requirements, and set the stage for smoother shipments in the future.

Next, we’ll share key tips to ensure your PSI process delivers the results you need—every time you import.

Key Considerations for a Successful PSI Outcome

When you’re managing a global supply chain, have you ever asked yourself, “How can I make sure my pre shipment inspection requirements are met every time—without unnecessary delays or costs?” If so, you’re not alone. Even the most experienced importers can run into trouble if the PSI process isn’t carefully managed. Let’s break down the practical steps you can take to ensure your inspections deliver real results and help you control your pre shipment inspection cost over the long term.

Proven Tips to Optimize Your Pre-Shipment Inspection

Imagine you’re about to receive a critical shipment. What can you do ahead of time to avoid last-minute surprises? Here’s a checklist of actionable strategies that leading importers use to get the most out of every inspection:

- Communicate Early and Clearly: Share your expectations, product specifications, and inspection standards with your supplier and inspection agency from the start. This reduces misunderstandings and ensures everyone is aligned on what’s required (Certainty Software).

- Define Detailed Specifications: Provide comprehensive product details, including drawings, material requirements, and regulatory standards. The more precise your instructions, the easier it is for inspectors to verify compliance.

- Set Acceptance Quality Limits (AQL): Don’t leave defect tolerance to chance. Agree on AQL levels that reflect your quality priorities and communicate these to both your supplier and the inspection team. This ensures everyone knows what’s acceptable—and what’s not.

- Book Inspections in Advance: Schedule your PSI early in the production process. Last-minute bookings can lead to rushed inspections or missed shipments, which may increase costs and risk incomplete checks (Movley).

- Customize Your Inspection Checklist: Tailor your checklist to the specific product and shipment. Include all relevant points—quantity, labeling, packaging, and compliance documents—to prevent critical items from being overlooked.

- Leverage Technology: Use digital inspection tools or platforms that provide real-time updates, photographic evidence, and instant reporting. This speeds up decision-making and helps you address issues before they escalate.

- Respond Promptly to Inspection Findings: Review reports as soon as they’re available and act quickly on any non-conformities. Timely corrective actions can prevent delays and reduce financial losses.

- Use Feedback for Continuous Improvement: Treat each inspection as an opportunity to refine your processes. Analyze recurring issues, share feedback with suppliers, and adjust your requirements to drive ongoing quality improvements.

Common Pitfalls to Avoid

Even with the best intentions, it’s easy to fall into traps that can undermine your PSI outcomes. Watch out for these common mistakes:

- Vague or incomplete inspection instructions

- Relying solely on supplier self-inspections

- Ignoring minor defects that could become larger problems later

- Delaying review of inspection reports, leading to shipment hold-ups

- Neglecting to budget for PSI in your overall pre shipment inspection cost, resulting in unexpected expenses

Building a Culture of Quality and Compliance

When you integrate these best practices into your workflow, you’ll notice a dramatic improvement in both the efficiency and reliability of your shipments. Proactive communication, precise requirements, and rapid response to feedback all contribute to a culture of quality—one where every shipment meets your standards and supports your business reputation.

Ready to put these tips into action? In the final section, we’ll recap the essential role of PSI in your quality assurance program and show you how investing in robust inspection practices pays off for your business.

Conclusion

When you think about the risks of global trade, do you ever wonder how a single shipment could impact your company’s reputation, finances, or customer relationships? That’s where a trusted pre shipment inspection agency becomes your safety net. Throughout this guide, you’ve seen how pre-shipment inspections (PSI) are not just a box to tick—they’re a cornerstone of quality control, risk mitigation, and compliance that can make or break your business success.

PSI: The Smart Investment for Quality and Security

Imagine the relief of knowing that every product leaving your supplier’s warehouse has been checked for defects, compliance, and accuracy. By implementing robust PSI practices, you:

- Reduce costly returns and disputes by catching issues before goods leave the factory.

- Protect your brand reputation by ensuring only compliant, high-quality products reach your customers.

- Streamline customs clearance with proper documentation, like a pre shipment inspection SGS certificate or third-party report.

- Build stronger supplier relationships through clear expectations and ongoing feedback.

- Gain actionable insights to drive continuous improvement across your supply chain.

Choosing the Right Partner for Peace of Mind

But not all inspection services are created equal. The difference between a smooth, risk-free shipment and a costly setback often comes down to the expertise of your inspection partner. That’s why experienced agencies like Eagle Eyes Quality Inspection stand out. Their certified inspectors, transparent reporting, and deep local knowledge give you the confidence that your shipments meet every requirement—every time.

In today’s fast-moving global market, investing in a reliable pre shipment inspection agency isn’t just a precaution—it’s a strategic advantage. By prioritizing thorough inspections and partnering with trusted experts, you’re not only safeguarding your current shipments but also building a foundation for long-term business growth and resilience.

Ready to take control of your supply chain and ship with confidence? Make pre-shipment inspection a core part of your quality assurance strategy, and let experienced partners help you deliver on your promises—every shipment, every time.

Frequently Asked Questions about Pre Shipment Inspection

1. What is a pre-shipment inspection and why is it important?

A pre-shipment inspection (PSI) is a quality control process conducted before goods leave the supplier. It verifies that products match buyer specifications, meet regulatory standards, and are free from defects. This helps importers avoid costly surprises, shipment delays, and protects their brand reputation by ensuring only compliant goods are shipped.

2. What are the main steps involved in the pre-shipment inspection process?

The process typically includes preparation (reviewing orders and planning), on-site inspection (checking quantity, quality, packaging, labeling, and compliance), and post-inspection (reporting findings and making decisions). Inspectors use sampling methods and detailed checklists to ensure thorough evaluation before shipment.

3. Who pays for pre-shipment inspection services?

The cost of pre-shipment inspection is usually covered by the importer or, in certain cases, the government of the importing country. Sometimes, if additional inspections are required, the seller may be invoiced for supplementary visits.

4. How do I choose the best pre-shipment inspection company in China?

Look for companies with ISO certifications, proven experience in your product category, transparent reporting, and strong customer support. Agencies like Eagle Eyes Quality Inspection offer certified inspectors, clear communication, and detailed reports, making them reliable partners for importers sourcing from China.

5. What documents should I expect after a pre-shipment inspection?

After PSI, you should receive a detailed inspection report summarizing findings, photos, defect rates, and compliance status. A pre-shipment inspection certificate may also be provided, confirming that goods meet required standards. These documents are crucial for customs clearance and quality assurance.