Aluminum Plate Inspection Process1. Pre-Inspection Preparation

Review Requirements:

Confirm specifications (thickness, alloy, surface treatment, tolerances, etc.) against the contract or technical agreement.

Reference standards: GB/T (China), ASTM (USA), EN (Europe), or customer-specific requirements.

Sampling Plan:

Follow AQL (Acceptable Quality Level) standards (e.g., AQL 1.0/2.5 per ISO 2859-1 or customer request).

Tools Preparation:

Micrometer, caliper, hardness tester, gloss meter, coating thickness gauge, etc.

2. Visual Inspection

Surface Quality:

Check for scratches, dents, oxidation spots, color differences, peeling, or bubbles.

Verify surface treatment (anodizing, painting, brushing, etc.) for uniformity and adhesion.

Edge Condition:

Ensure smooth edges without burrs or cracks.

Cleanliness:

Free from oil stains, dust, or chemical residues.

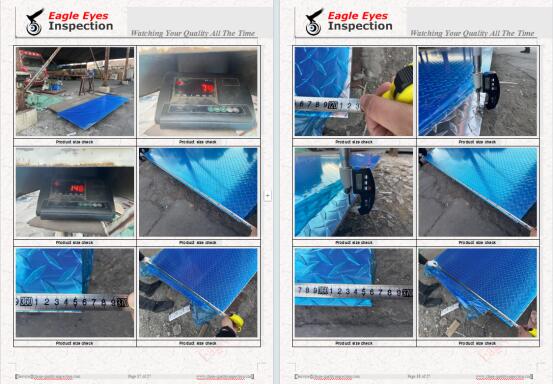

3. Dimensional Inspection

Thickness:

Measure at multiple points (corners + center) using a micrometer (±0.1mm tolerance).

Width/Length:

Verify with a tape measure or caliper; check diagonal deviation (e.g., ≤2mm/m).

Flatness:

Place on a flat surface and check warping with a feeler gauge (e.g., ≤1mm/m).

4. Material & Performance Testing

Alloy Verification:

Check material certificate (e.g., 6061, 5052); use a spectrometer if needed.

Mechanical Properties:

Hardness (Webster), tensile strength, elongation (third-party test reports).

Coating Tests (if applicable):

Adhesion (cross-cut test), coating thickness (dry film thickness gauge).

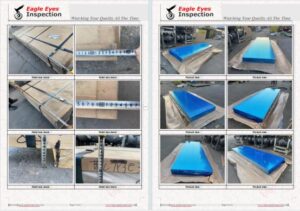

5. Packaging & Marking

Packaging Integrity:

Ensure protective film/paper, foam separators, and pallet/wooden crate stability.

Labeling:

Check batch number, alloy grade, dimensions, and handling instructions.