Key Inspection Processes for Zippers

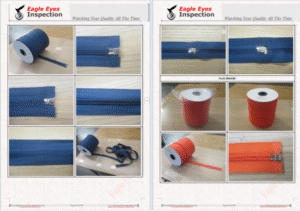

Visual Inspection

Check for consistent color, finish, and surface defects (scratches, dents, or discoloration).

Verify alignment of teeth/slider and ensure no missing or misaligned elements.

Functionality Test

Test the slider’s smooth movement up and down (no jamming or stiffness).

Ensure the zipper locks properly (if applicable) and stays closed under slight tension.

Strength Testing

Pull Test: Apply force to the zipper tape and teeth to verify durability (meets specified kgf/lbs standards).

Slider Retention Test: Ensure the slider does not detach during normal use.

Size/Dimension Check

Confirm length, width, and tooth size match specifications using calipers or measuring tape.

Material Verification

Validate material composition (e.g., metal/plastic teeth, polyester/nylon tape) against requirements.

Endurance Test (Sampling)

Repeatedly open/close the zipper (e.g., 500+ cycles) to assess wear resistance.

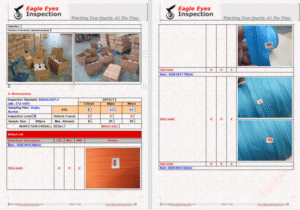

Packaging & Labeling

Inspect packaging for damage and confirm labels (size, material, batch number, etc.) are accurate.